Metal and plastic prototype parts customization, CNC turning small batch prototype parts production, youde offers competitive prices, strict quality assurance, and fast turnaround.

Quotes within 4 hours,short manufacturing turnaround as fast as 2 days.

Reasonable price with high quality services,offer most cost-effective approach for your project.

Engineering support for material selection and manufacturability.

Delivery as we promised,able to react flexibly to customer requests in short time.

| Name | MM |

| Max Dia | 240 MM |

| Max length | 610 MM |

We strictly control CNC turning tolerances according to ISO standards

| Type | Range |

| Linear size | +/- 0.05 mm |

| Hole diameter | +/- 0.025 mm |

| Shaft diameter | +/- 0.025 mm |

| Dimension limit | 1100*800*450 mm |

With impact resistance, low-temperature resistance, heat resistance, chemical resistance, and easy processing.

It has the characteristics of heat resistance, wear resistance, chemical corrosion resistance and easy processing.

Corrosion resistance, excellent electrical insulation, high melting point, rigidity, hardness and strength.

The conductivity and plasticity are good, but the strength and hardness are poorer.

It has the characteristics of resistance to weak corrosive media such as air, steam, and water;

| Picture | Name | Description | Material | Color | Surface finish |

|---|---|---|---|---|---|

|

Electroplate | Electroplate can be used as functional, decorative or corrosion related,and it is apply to various industries,especially the automotive industry | Aluminum,Steel,Stainless Steel | Natural | smooth and shiny |

|

Sand blasting | The sandblas can make parts smooth surfaces and matte textures.it is mainly used for visualappearance. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, Stainless Steel, Steel | Natural | Matte |

|

Polishing | Polishing is the process of producing a smooth and shiny surface by physically rubbing or chemically reacting a part. This process produces surfaces with significant specular reflections. | Aluminum,Brass,Stainless Steel,Steel | Natural | smooth surface |

|

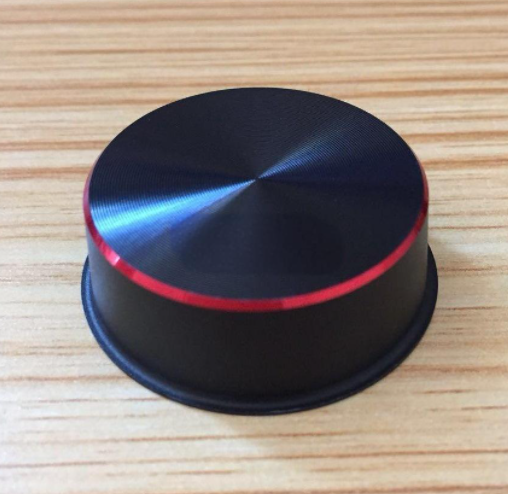

Anodizing | Anodizing is improves corrosion resistance, enhances wear resistance and hardness, and protects metal surfaces. Widely used in mechanical parts, aviation parts, auto parts, precision instruments, etc. | Aluminum | Natural,clear, black, grey, red, blue, gold. | Smooth surface, matte finish. |

|

Sanding | It is rub the part surface to remove machining marks and burrs by sandpaper, and make the product smooth and beautiful. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, Stainless Steel, Steel | Natural | smooth surface |

|

Powder coating | Powder coating is a coating that is applied as a free-flowing dry powder. it is different from the traditional liquid coatings, the powder coatings are typically applied electrostatically and then cured with heat or UV light. | Aluminum,Stainless Steel,Steel, | Black White gray | glossy or semi-glossy |

|

Painting | The process is sprayed with liquid paint. The appearance looks more beautiful after spraying various colors. At the same time, the life and service life of the product can be extended due to an extra layer of protection. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, stell | Custom color, Adjust the liquid painting to get the custom color. | smooth, glossy, matte finish, mirror finish |

|

Engraving | The desired font or pattern can be obtained by instantaneous melting and vaporizing physical denaturation under laser engraving irradiation | Plastic,aluminum,stainless steel,steel | Black,Natural | Not applicable |

|

High Glossy Painting | High-gloss coatings have good rust resistance and durability, excellent adhesion and impact resistance, excellent hydrochloric acid resistance, and high heat resistance. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, stell | Custom color, | Shiny, Smooth |

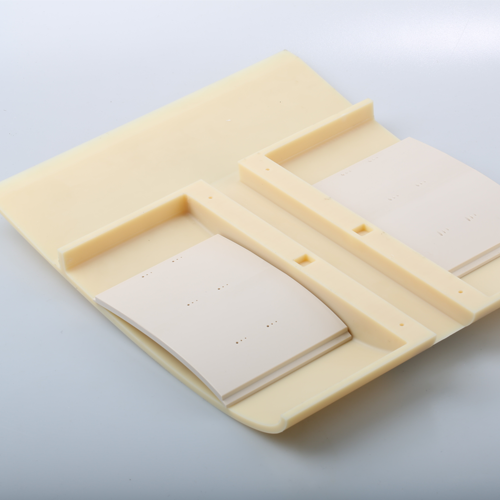

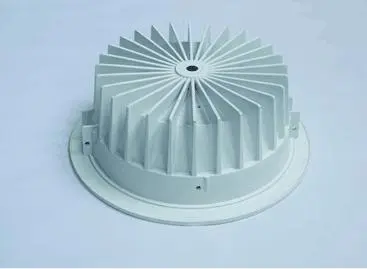

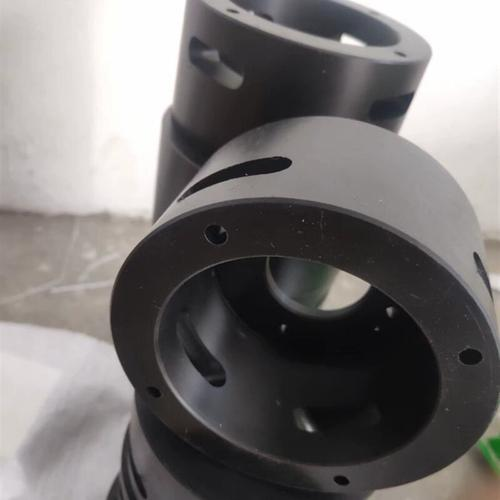

CNC turning is one of the most widely used machining. It is mainly used for the inner and outer cylindrical surfaces of shaft parts or disc parts, the inner and outer conical surfaces of any taper angle, the complex inner and outer curved surfaces, the cylindrical and conical threads etc., and can be used for grooving, drilling, reaming and reaming, holes etc.

CNC turning provides a cost-efficiency process to make parts that are commonly symmetrical about an axis of revolution. The raw materials to be cut rotates on the machine when a cutter fed into the rotating workpiece. It can be made include variety of taper, fillet and threaded surfaces etc. We offer full-service CNC turning of a variety of materials. Our experienced staff and advanced machines that ensure all the prototypes will meet your expectations.

The CNC turning process involves shaping the material by moving a single-point cutting tool parallel to the axis of rotation while the lathe is stationary and the raw material is turned. Precise measurements are entered into the machine via CAD software.

CNC milling is a machining process that produces custom-designed parts or components by gradually removing material from a workpiece using rotating multi-point cutting tools and computer control. These systems typically have three linear degrees of freedom. When the workpieces remain stationary, they can move freely around the X, Y and Z axes. This limited size operation reduces the speed of the operation, making milling more suitable for prototyping and smaller production runs.

CNC turning is a manufacturing process that involves holding rods of material in a chuck and rotating them while a tool is fed into the workpiece to remove material until the desired shape is achieved. Since the desired shape is achieved by removing material, it is also known as subtractive machining.

CNC turning is a manufacturing process in which a rod of material is held in a chuck and rotated while a tool is fed into the workpiece to remove material to form the desired shape. A tool-attached turret (shown in the picture) is programmed to move to the raw material bar and remove material to create the programmed result. This is also called "subtractive machining" because it involves material removal. If the center has both adjustment and milling functions, such as the one above, the rotation can be stopped to allow other shapes to be milled.

General CNC machining usually refers to computer digital control precision machining, CNC machining lathes, CNC machining milling machines, CNC machining boring and milling machines, etc. CNC machining is programmed and controlled according to the programmed program, usually G code, to make the machine tool process. G-code digital language can control the machining process of CNC machine tools. The tool control system uses different position coordinates to control the tool feed, spindle speed, coolant and other functions.

The machining accuracy of CNC turning has been increased from 10 μm to 5 μm, and the precision machining center has increased from 3 to 5 μm to 1 to 1.5 μm, and the ultra-precision machining accuracy has begun to enter the nanometer level (0.01 μm).

Precision turning parts are high-precision hardware turning parts which are processed and operated by lathe machine tools, CNC lathes and other machines. Its precision can reach 0.005mm~0.1mm, and the products include steel, stainless steel, brass, aluminum, copper, bronze, high-precision lathe parts of different shapes and sizes.

Contact us today to learn how we can help you. Get a quote