Quotes within 4 hours,short manufacturing turnaround as fast as 2 days.

Reasonable price with high quality services,offer most cost-effective approach for your project.

Engineering support for material selection and manufacturability.

Delivery as we promised,able to react flexibly to customer requests in short time.

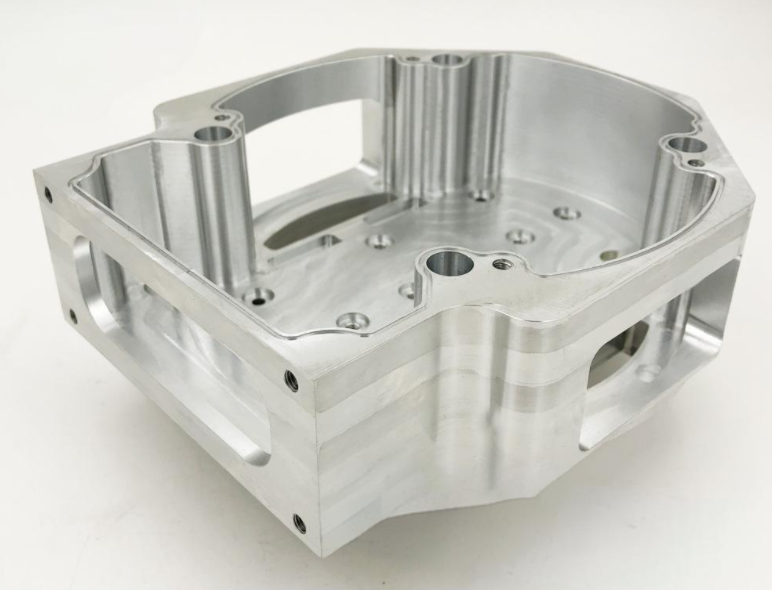

Our professional rapid prototyping service can ensure that your order can be completed quickly within the specified time limit without additional expenses.

24/7 service

It has the characteristics of resistance to weak corrosive media such as air, steam, and water.

The conductivity and plasticity are good, but the strength and hardness are poorer.

Corrosion resistance, excellent electrical insulation, high melting point, rigidity, hardness and strength.

It has the characteristics of heat resistance, wear resistance, chemical corrosion resistance and easy processing.

With impact resistance, low-temperature resistance, heat resistance, chemical resistance, and easy processing.

| Picture | Name | Description | Material | Color | Surface finish |

|---|---|---|---|---|---|

|

Electroplate | Electroplate can be used as functional, decorative or corrosion related,and it is apply to various industries,especially the automotive industry | Aluminum,Steel,Stainless Steel | Natural | smooth and shiny |

|

Sand blasting | The sandblas can make parts smooth surfaces and matte textures.it is mainly used for visualappearance. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, Stainless Steel, Steel | Natural | Matte |

|

Polishing | Polishing is the process of producing a smooth and shiny surface by physically rubbing or chemically reacting a part. This process produces surfaces with significant specular reflections. | Aluminum,Brass,Stainless Steel,Steel | Natural | smooth surface |

|

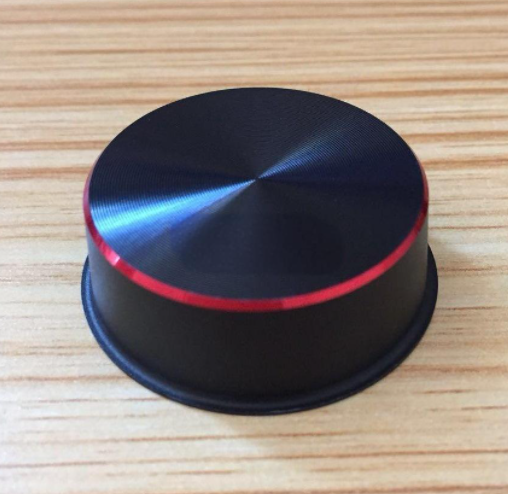

Anodizing | Anodizing is improves corrosion resistance, enhances wear resistance and hardness, and protects metal surfaces. Widely used in mechanical parts, aviation parts, auto parts, precision instruments, etc. | Aluminum | Natural,clear, black, grey, red, blue, gold. | Smooth surface, matte finish. |

|

Sanding | It is rub the part surface to remove machining marks and burrs by sandpaper, and make the product smooth and beautiful. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, Stainless Steel, Steel | Natural | smooth surface |

|

Powder coating | Powder coating is a coating that is applied as a free-flowing dry powder. it is different from the traditional liquid coatings, the powder coatings are typically applied electrostatically and then cured with heat or UV light. | Aluminum,Stainless Steel,Steel, | Black, White, gray | glossy or semi-glossy |

|

Painting | The process is sprayed with liquid paint. The appearance looks more beautiful after spraying various colors. At the same time, the life and service life of the product can be extended due to an extra layer of protection. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, stell | Custom color, Adjust the liquid painting to get the custom color. | smooth, glossy, matte finish, mirror finish |

|

Engraving | The desired font or pattern can be obtained by instantaneous melting and vaporizing physical denaturation under laser engraving irradiation | Plastic,aluminum,stainless steel,steel | Black,Natural | Not applicable |

|

High Glossy Painting | High-gloss coatings have good rust resistance and durability, excellent adhesion and impact resistance, excellent hydrochloric acid resistance, and high heat resistance. | plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, stell | Custom color | Shiny, Smooth |

Please send us your 3D drawings with a list about material, quantity and finish. Then we will send you the quotation within 24 hours.

Polishing, Passivating, Anodized, Sandblasting, Painting, all kinds of plating( chrome plating, nickel plating, gold plating, silver plating).

We accept the payment term is: 50% as deposit, balance before the shipment. We can accept payment by Paypal.

No, there is no MOQ required, our facility specializes in low volume production (1pcs to 1000pcs) of rapid prototyping.

Contact us today to learn how we can help you. Get a quote