Milling Technical Capability

3-axis/4-axis CNC machining is the simplest and most common form of versatility . Typically used to machine prototype parts with simple geometries and low tolerance levels , which can greatly reduce tool costs and fast turnaround delivery .

Maximum Milling size

| Machining Process |

MM |

| CNC Milling |

1100*800*450MM |

Tolerances for CNC Milling

We strictly control CNC Milling tolerances according to ISO standards

| Type |

Range |

| Linear size |

+/- 0.05 mm |

| Hole diameter |

+/- 0.025 mm |

| Shaft diameter |

+/- 0.025 mm |

| Dimension limit |

1100*800*450 mm |

CNC milling

With up to 50 metal and plastic materials available for CNC milling, Youde Prototype gives you more material options.

Aluminum

Has good ductility, heat resistance, and machinability.

Stainless Steel

It has the characteristics of resistance to weak corrosive media such as air, steam, and water;

Steel

It has high strength, plasticity, heat resistance and good toughness.

Brass

Brass has strong wear resistance.

Copper

The conductivity and plasticity are good, but the strength and hardness are poorer.

Polyethylene

Corrosion resistance, excellent electrical insulation, high melting point, rigidity, hardness and strength.

Nylon

It has the characteristics of heat resistance, wear resistance, chemical corrosion resistance and easy processing.

ABS Plastic

With impact resistance, low-temperature resistance, heat resistance, chemical resistance, and easy processing.

Surface Treatment of CNC Milling Prototype Parts

All CNC Milling metal and plastic prototype parts can be finished for appearance, surface finish, hardness and color.

| Picture |

Name |

Description |

Material |

Color |

Surface finish |

|

Electroplate |

Electroplate can be used as functional, decorative or corrosion related,and it is apply to various industries,especially the automotive industry |

Aluminum,Steel,Stainless Steel |

Natural |

smooth and shiny |

|

Sand blasting |

The sandblas can make parts smooth surfaces and matte textures.it is mainly used for visualappearance. |

plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, Stainless Steel, Steel |

Natural |

Matte |

|

Polishing |

Polishing is the process of producing a smooth and shiny surface by physically rubbing or chemically reacting a part. This process produces surfaces with significant specular reflections. |

Aluminum,Brass,Stainless Steel,Steel |

Natural |

smooth surface |

|

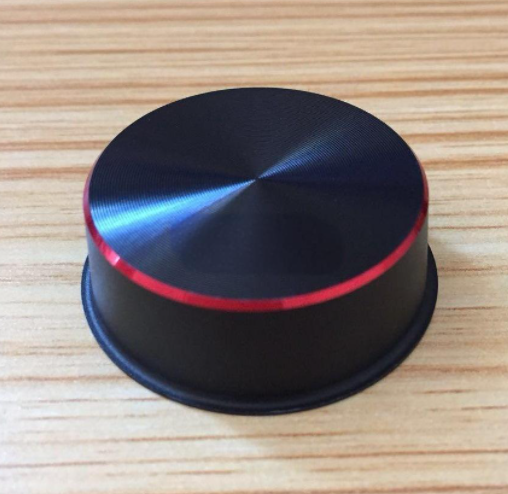

Anodizing |

Anodizing is improves corrosion resistance, enhances wear resistance and hardness, and protects metal surfaces. Widely used in mechanical parts, aviation parts, auto parts, precision instruments, etc. |

Aluminum |

Natural,clear, black, grey, red, blue, gold. |

Smooth surface, matte finish. |

|

Sanding |

It is rub the part surface to remove machining marks and burrs by sandpaper, and make the product smooth and beautiful. |

plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, Stainless Steel, Steel |

Natural |

smooth surface |

|

Powder coating |

Powder coating is a coating that is applied as a free-flowing dry powder. it is different from the traditional liquid coatings, the powder coatings are typically applied electrostatically and then cured with heat or UV light. |

Aluminum,Stainless Steel,Steel, |

Black, White, gray |

glossy or semi-glossy |

|

Painting |

The process is sprayed with liquid paint. The appearance looks more beautiful after spraying various colors. At the same time, the life and service life of the product can be extended due to an extra layer of protection. |

plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, stell |

Custom color, Adjust the liquid painting to get the custom color. |

smooth, glossy, matte finish, mirror finish |

|

Engraving |

The desired font or pattern can be obtained by instantaneous melting and vaporizing physical denaturation under laser engraving irradiation |

Plastic,aluminum,stainless steel,steel |

Black,Natural |

Not applicable |

|

High Glossy Painting |

High-gloss coatings have good rust resistance and durability, excellent adhesion and impact resistance, excellent hydrochloric acid resistance, and high heat resistance. |

plastic:ABS,PC,PMMA,POM,PA,PPS,PBT etc, Aluminum, Brass, stell |

Custom color |

Shiny, Smooth |

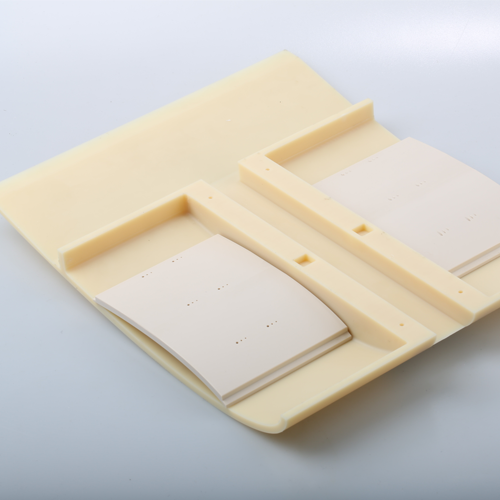

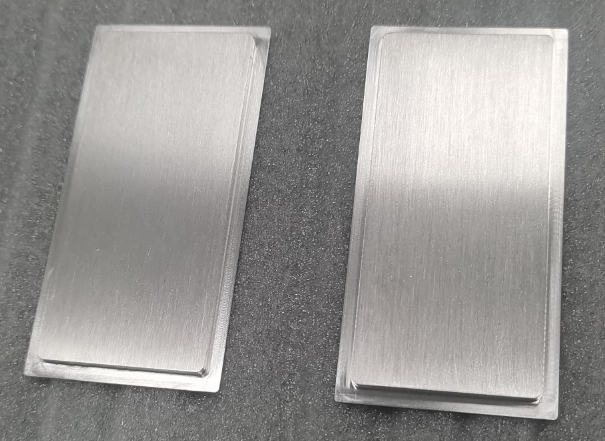

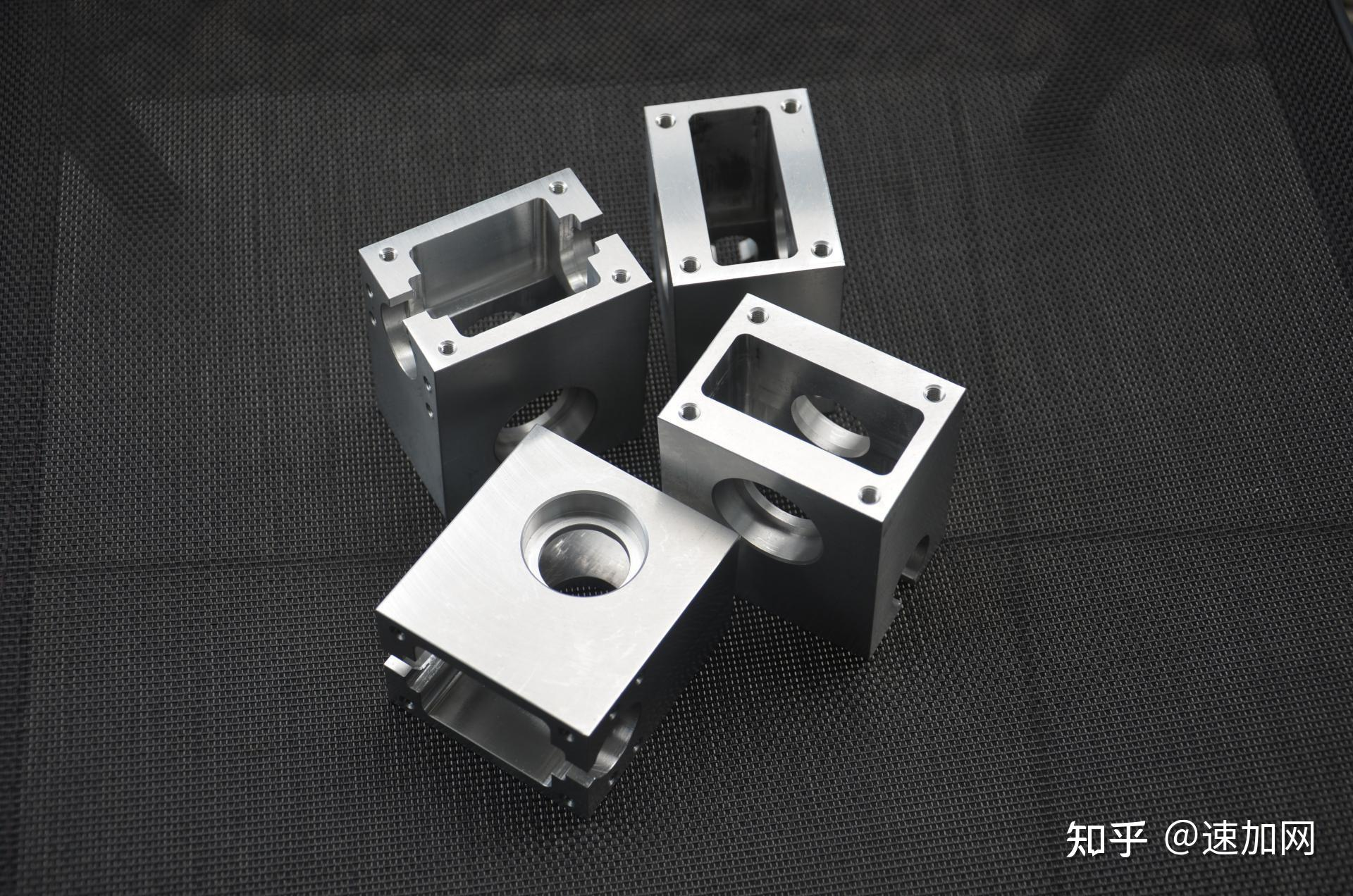

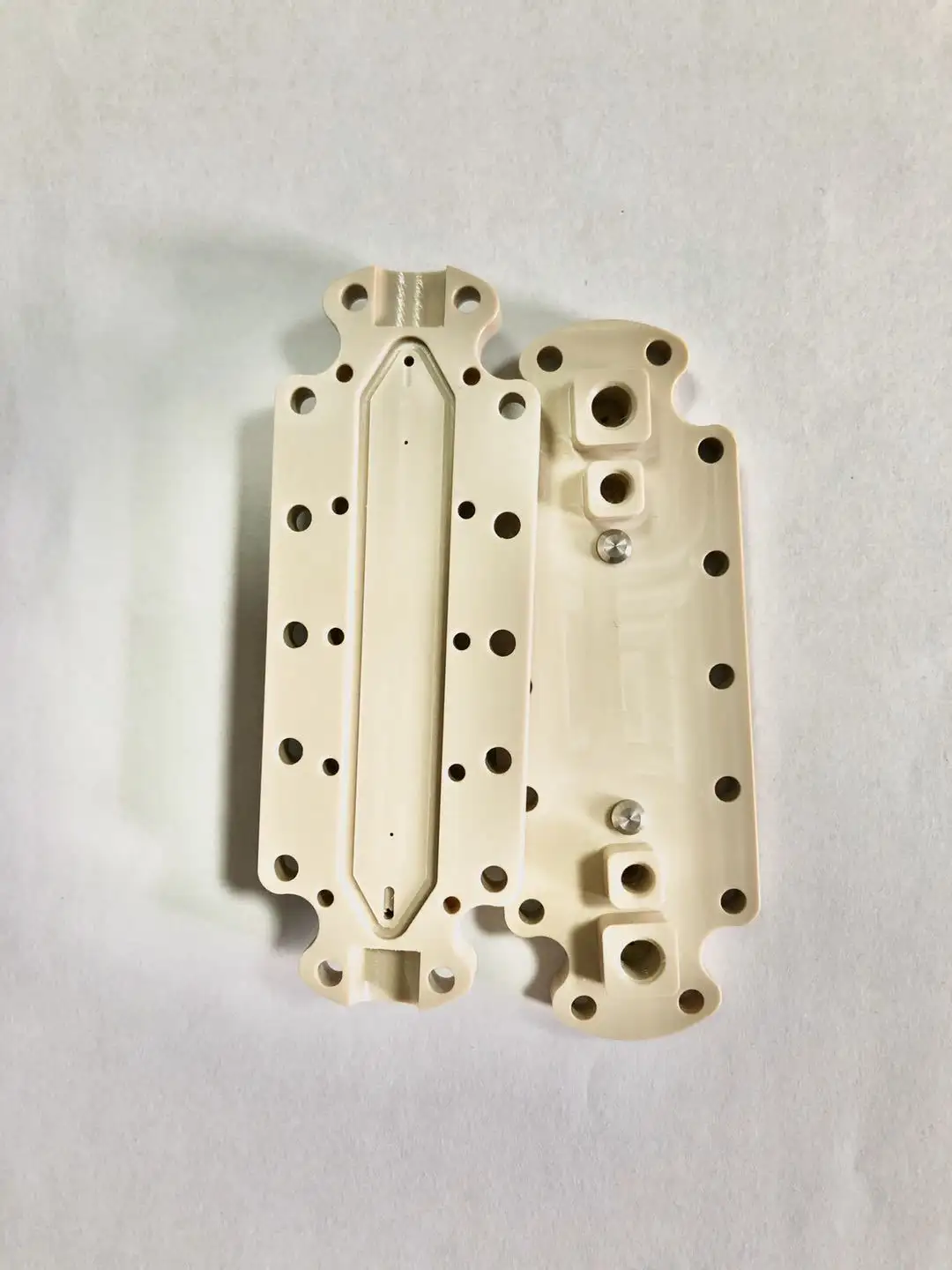

Picture appreciation of CNC milling prototype parts

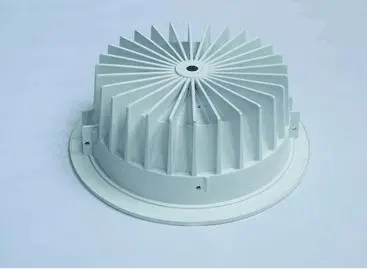

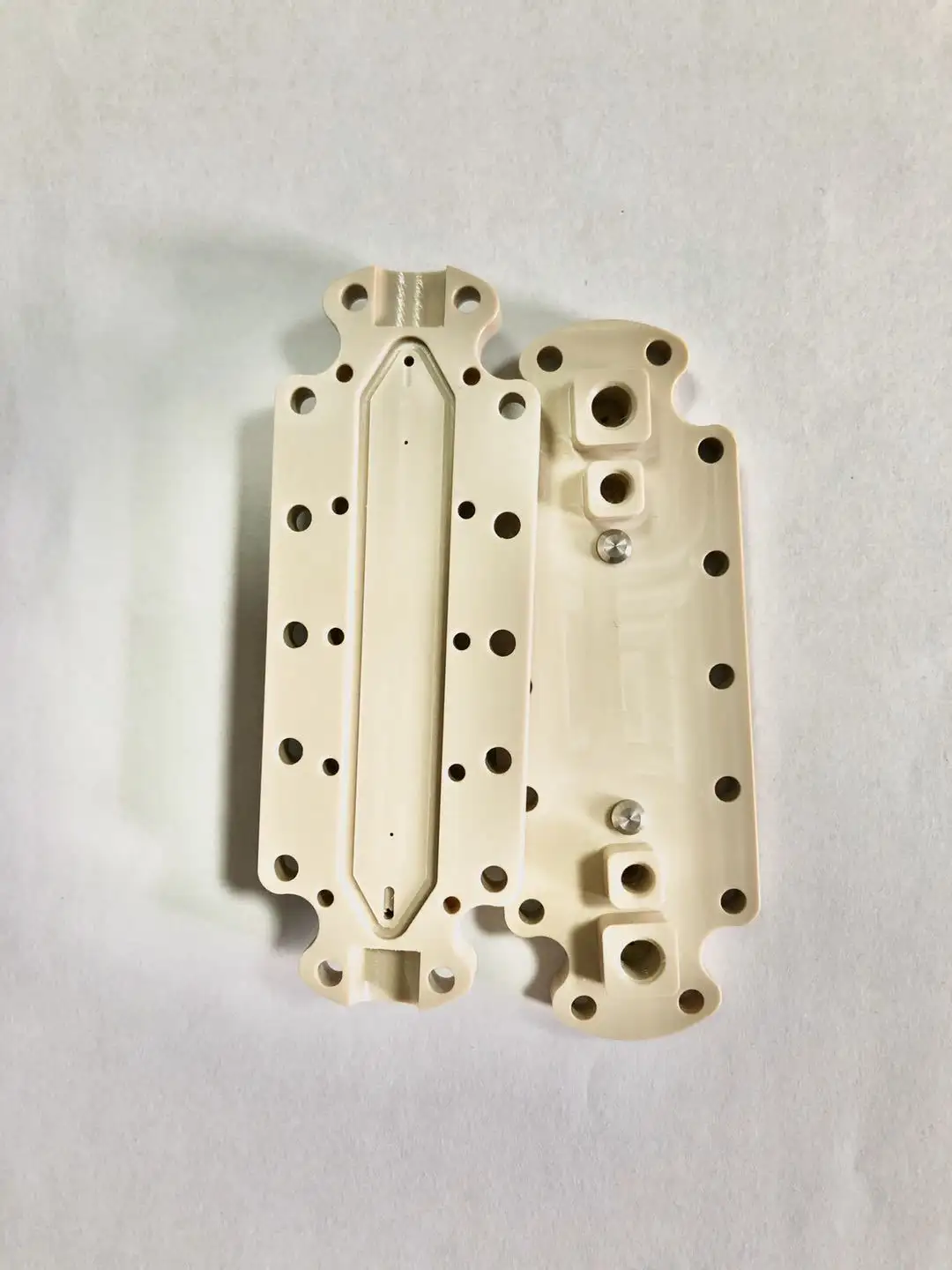

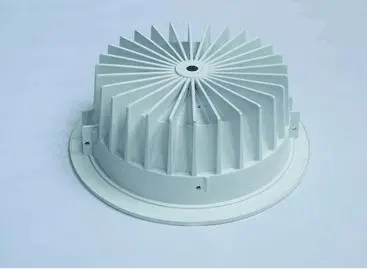

CNC Milling Metal Parts

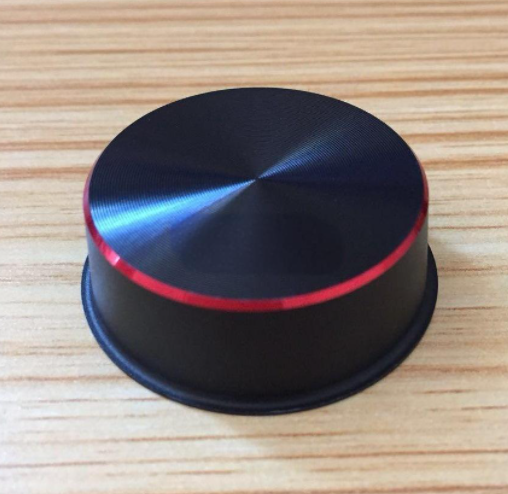

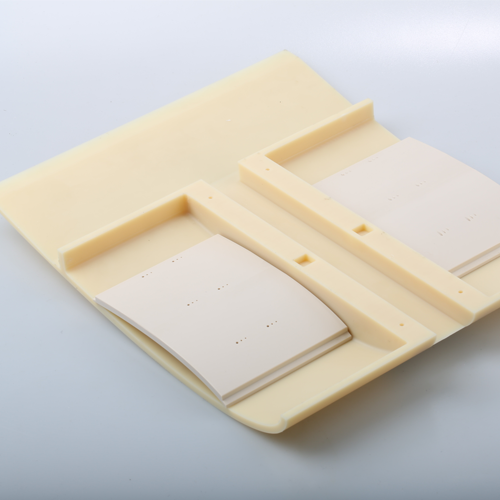

CNC Milling of Plastic Parts

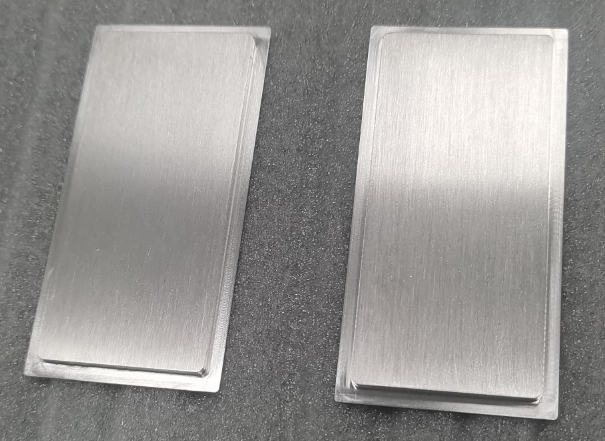

CNC Milling of Plastic Parts

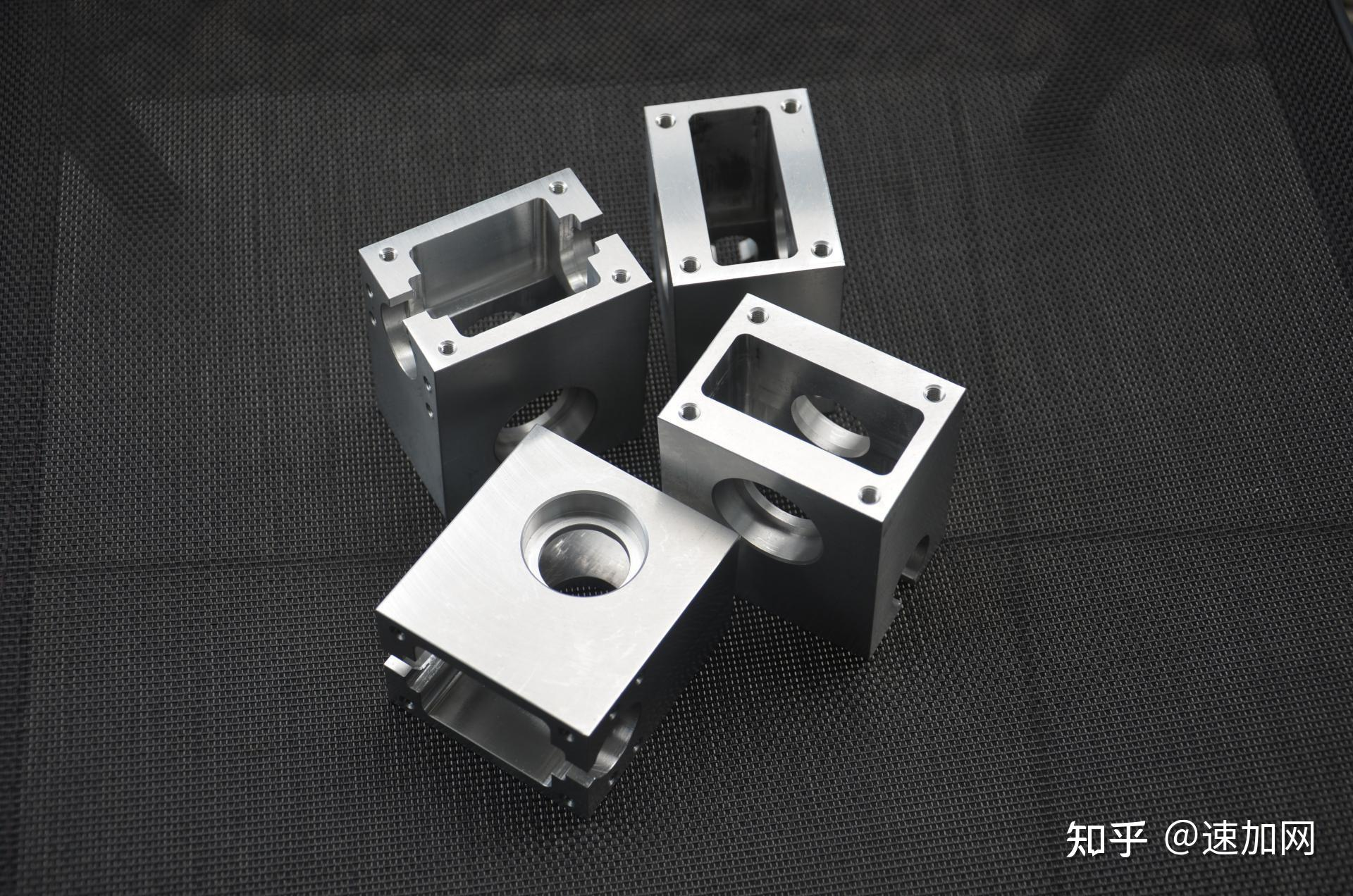

CNC Milled Prototype Parts

What is CNC Milling?

CNC milling , or Computer Numerical Control Milling , is a machining process that employs computer-controlled and rotating multi-point cutting tools to gradually remove material from a workpiece and produce a custom-designed part or product . The process is suitable for machining a variety of materials such as metal , plastic , wood , and producing a variety of custom-designed parts and products .

CNC milling is a mechanical process that includes drilling , turning , and various other machining processes , which means that material is removed from a part by mechanical means , such as the action of a milling machine's cutting tool .

FAQ

1.What are the pros and cons of CNC milling?

Advantages of CNC milling :

1 . CNC milling can automatically process and reduce repetitive work .

2 . CNC milling has high machined accuracy and can manufacture higher tolerance levels .

3 . CNC milling can manufacture complex geometrical parts .

4 . CNC milling has high processed efficiency . When the shape and size of the parts need to be changed , only the CNC program needs to be changed , saves production preparation time .

Disadvantages of CNC milling:

1. Higher technical requirements for operators and machine maintenance personnel.

2. The purchase cost of CNC machine tools is relatively expensive.

2.Why is CNC milling used?

CNC milling is able to maintain very tight geometric tolerances for many aspects of some key features such as diameter , true position , profile and flatness . With increasingly affordable tooling costs and the ability to create a wide range of complex parts , CNC milling is a popular project for full-scale fabrication of unique precision parts from prototype to full-scale fabrication .

3.what is cnc milling part?

CNC milling can process complex prototype parts according to the program. CNC milling is suitable for the processing of workpieces with different structures and shapes. It can complete drilling, boring, reaming, plane milling, bevel milling, slot milling, milling surface ( cam), tapping, etc.

4.What is CNC milling used for?

CNC milling is a machining process suitable for producing high-precision, high-tolerance parts in prototype, one-off, and small to medium production runs. The versatility of the milling process allows it to be used in a wide range of industries and for a variety of part features and designs, including slots, chamfers, threads and pockets.

5.Is CNC the same as milling?

Compared with ordinary milling machines, CNC milling machines have the characteristics of high processing accuracy, complex shapes of processed parts, and wide processing ranges. When processing on an ordinary milling machine, it is difficult to ensure the dimensional accuracy, shape and position accuracy and surface roughness of the workpiece, and a CNC milling machine should be selected for processing.

6.What is the difference between CNC milling and turning?

CNC turning is a rotary motion of the workpiece, and a feed motion of the tool, that is, a linear or curved translational motion, without rotation, suitable for processing round surfaces. CNC milling refers to cutting metal workpieces with a circular multi-blade tool that can be rotated, and is one of the main methods of plane machining.